The PocketShip requires aadditional hull ballast in the 150-200lb (70-90kg) range. This is in addition to the lead that was smelted into the centerboard and skeg. The manual uses lead, but we have over a hundred kilograms of steel rebar ballast we used for a time to level the floating house, so we decided to…

PocketShip: First water test

Having gotten the boat onto the trailer a few days ago, we decided to try a first test of PocketShip in the water. Since we live in a floating house in a pond in the middle of our land, and we built PocketShip in a tent on the side of the pond, in only made…

PocketShip: moving the boat onto the trailer

Hoisting the boat up on a winch Pushing the trailer underneath PocketShip on the trailer for the first time

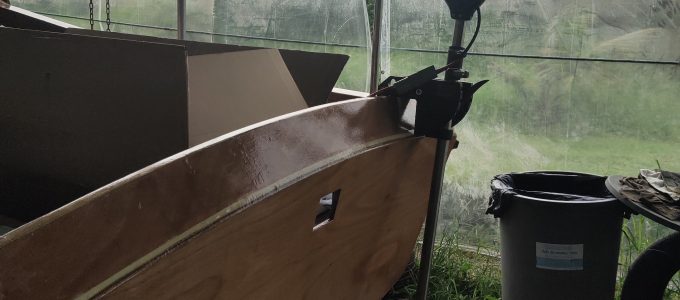

PocketShip: Mounting an electric outboard

It will require some additional pieces to get the outboard to mount properly on the transom, but we ordered and received a Carroute 160 ft-lb electric outboard trolling motor. It will be interesting to test.

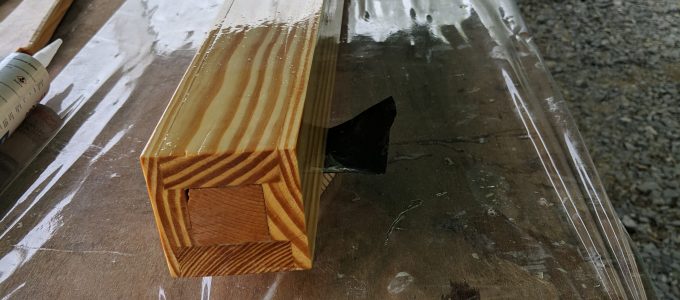

PocketShip: Building the various spars

The mast design on the PocketShip is basically a hollow box sealed on the ends by a length of solid core for strength. Given how short it is, this was the easiest way for the designer to make it light and still buildable by home builders. But the other spars are solid. Finished mast Testing…

PocketShip : Welding our own custom trailer

We decided to weld our own custom trailer for towing the small boat, since we have access to good welders.

Pocketship : Cut the window ports

Window ports cut and round polycarbonate windows placed inside

PocketShip: fiberglassing the top hull

We returned the boat to the right side up after finishing painting the bottom side of the hull. Now we mostly just have to finish the fiberglassing of the top hull and cutting the window holes and the hull will mostly be complete. This is also the first time I get to see the boat…

Pocketship : painting the hull #3

After painting the hull blue, we marked off the boot strip using tape. All taping was done with the aid of a laser level. It marks a perfectly straight line on the hull in green laser that we can trace with the tape. Green laser line above bottom tape strip Zoom in to see the…

-

Recent Posts

Recent Comments

Archives

Categories