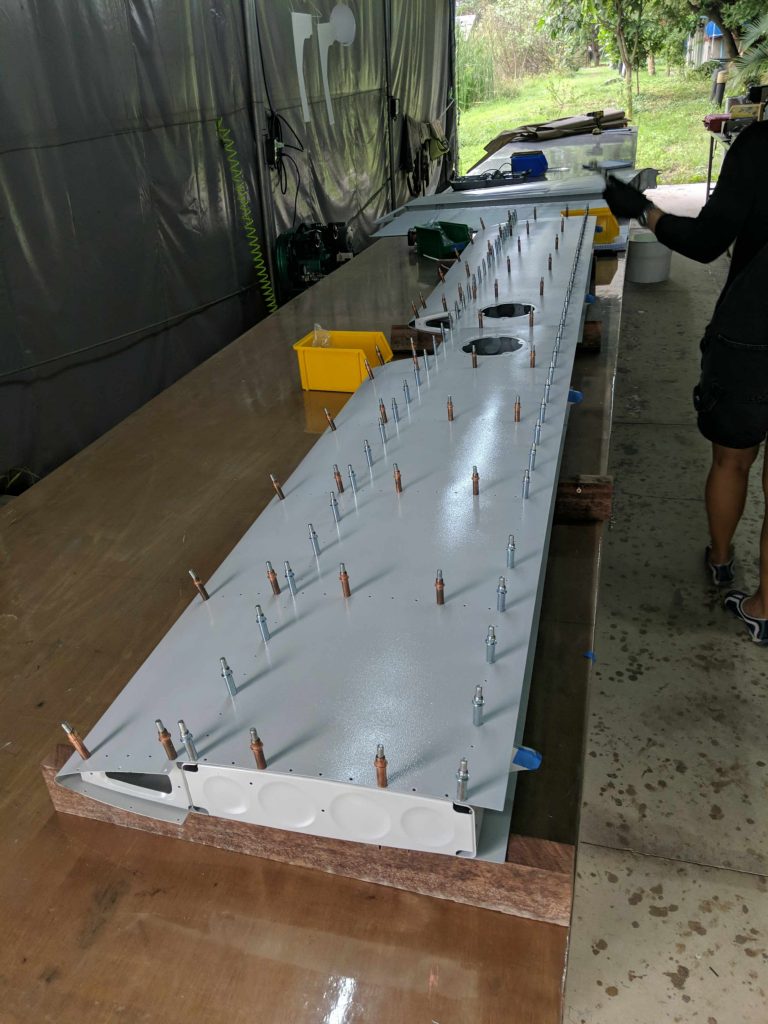

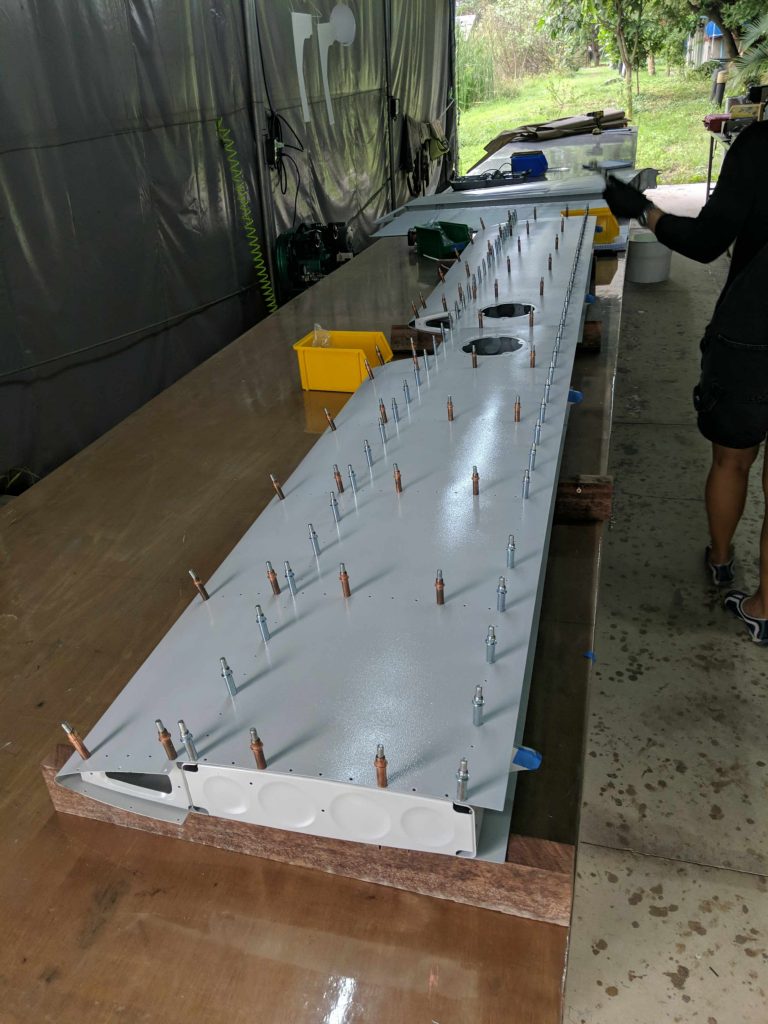

The horizontal stabilizer is larger and slightly more involved than the vertical stabilizer, but still looks fairly straightforward if we can be careful enough following the instructions exactly.

The horizontal stabilizer is larger and slightly more involved than the vertical stabilizer, but still looks fairly straightforward if we can be careful enough following the instructions exactly.

Copyright © 2026, Man In Black Projects. Proudly powered by WordPress. Blackoot design by Iceable Themes.