These are made from the same type of aluminum piece that aluminum doors and windows are made from, but bent in the middle. The aluminum both mounts the LED and acts as a heat sink.

These guys bounce the light off of the wall at about 45 degrees making a nice soft light in the room:

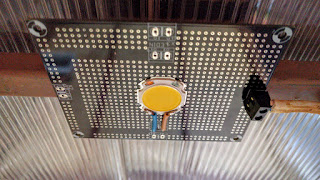

The ceiling lights have gone through a few iterations. The key is that need for a heatsink. We settled on a PCB design that makes mounting the LED easy (solder it on), but also makes wiring easy. The LED is wired to a +24V and GND trace and then wiring connectors are added depending on the configuration around the particular light. Connectors can be added in each of the 4 sides to make end lights (1 connector), straight throughs (2 connectors opposite each other), 90 degree turns (2 connectors 90 degrees from each other), Y splits (3 connectors), or even 4 way junctions. Here is one with the plastic cover removed:

The many through holes in the PCB help radiate the heat from the board. This one is an end light, so it only has one connector.

Here is a straight through with two connectors and the 3D printed plastic cover for the LED:

We are now experimenting with an improved design that has a little bit of a cylindrical piece coming down to reduce the glare from the light on the ceiling from across the room.

But having light in each room at the flick of a switch is quite nice. And every light in the house is dimmable and powered off of the solar powerd (battery storage) DC circuit, so the lights don’t go off during a mains power out.