We have begun building a prototype of our custom steel pontoons that Kong helped us work out a simple engineering design for.

Here are the steel plates that we will use for the “skin” of the pontoon:

In this picture, the workers are carefully covering the steel in high quality anti-rust coating. After the pontoons are finished building, we will coat it in another layer of the anti-rust, and then a marine grade epoxy paint to protect it while it is in the water.

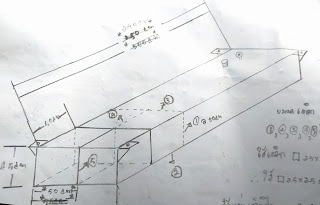

And here is the beginning of the steel frame that will support the inside of the pontoon on Friday:

To understand why in the world we are building pontoons, I will take a step back and summarize my plans for watercraft on our pond…

I am hoping to build a single storey floating house on the pond as our main residence that will be totally disconnected from land most of the time and can move around and reorient itself in the pond at will. It will use GPS and other positioning sensors to know where it is and maintain position over time (as well as avoid crashing into things).

We are also planning to build a ferry boat to ferry us from the edge of the pond to the floating house that will also hopefully be autonomous and use GPS and other sensors to navigate around the pond (and also avoid crashing into things).

Initially, I was planning on using plastic 200L drums as flotation devices under both house and ferry boat, but eventually gave up due to four significant negatives.

- The 200L drums are quite tall. At about 90cm high, they raise the height (and thus the CG) of whatever craft is on top of them. Due to the smaller size of the ferry boat, this extra height is undesirable from a stability standpoint. For the house, it raises the profile of the house and increases the wind resistance. From an aesthetic standpoint, I would also like to be able to stand on the balcony and look out and feel like I am standing just 30-40 cm higher than the surface of the water.

- I am targetting about 15,000kg of flotation on the house for a factor of 3x safety margin on my target of 5,000kg weight of the house itself. This comes out to 75x 200L drums. In terms of checking all of these to make sure there aren’t any cracks or leaks, 75 of them is really too much. And how to access the ones that are under the refrigerator? Under the bathroom?

- I don’t know how long the plastic PVC drums will last in the water. The outer ones may be exposed to direct sunlight, and all of them have a compression pressure on them due to the water. Since they are more designed for outward pressure (holding stuff), I have no idea how long they will last. And given that there may be 75 of them to maintain, this is a problem.

- I don’t really have a good way to “dry dock” the house. In a real pinch, I might be able to find a way for a crane to come out to the land and lift the whole house out of the water, but this risks damaging the house, and is quite inconvenient. So I would like the pontoons to be maintainable while the house continues to float in the water. So if there is a problem and one of the floats needs replacement, I need ways to get under the house and unlock whichever one has problems (wherever it is under the house), fill it up with water so that I can swim it out, fill a new one with water so that I can swim it in, and then somehow get a water pump in under the house to pump the water out of the new drum so that it becomes a flotation device again. All of this has to be done without drowning, electrocuting myself, or tearing the house apart to access things.

So I’ve been looking for somewhere to source custom built pontoons to put house and ferry boat on top of. But to no avail.

Finally Kong suggested we try building our own. And if you have been reading my blog for a while now, you know how happy I am to try building something most people just go out and buy. Particularly when none of the options on the market suits my application well.

Most pontoons I’ve read about are made from aluminum, but working with aluminum is much more difficult than working with steel. The primary welder on our construction crew used to work at a place that makes pressurized steel air tanks, so he should have the welding skills needed for this. And since the pontoons will be used on a small pond without any serious wave action, and I don’t care at all about “top speed” so hydrodynamics isn’t important. So I thought “what the hell? Let’s take a crack at it!”

I spec’d out a 3.5m x 1.1m x 45cm boxy pontoon to get a volume of about 1,730L. If the steel weighs about 250kg, this comes out to 1,500kg of flotation per pontoon. This would allow 10 of them to support the entire house. And if it is done as 2 rows of 5, then every pontoon can be accessed from the very edge of the house along the balcony to open it up and inspect it to make sure there is no water leaking inside. A simple hatch on the balcony would allow for this without too much difficulty. Then 5 small hatches down the middle of the house would allow me to access the other side of the pontoons to unbolt them in the event I need to replace one. If I need to pump water in, I can do it from the access hatch, so all maintenance can be done from the house while I am still dry. This will be much more convenient than dealing with 75x 200L drums.

For the prototype, we scaled it down to 2.4m x 1m x 35cm for the ferry boat. Two of these should float it just fine. And since one can easily source 2.4m x 1.2m steel plates, it was easy to get the materials. (Larger sizes of plates are available but require bulk purchases in numbers that might make sense for the 10 pontoons plus a few spares on the floating house but not for a prototype.)

So we went ahead and ordered the materials, started coating it to protect it from rust, and began welding.

I am hoping it will be ready for a simple pressurized air test within a week or two to find any holes in the welding so that we can fill them. Then we should be ready for a water test. And then I will know how crazy was this idea. Or maybe not?