The filaments used for 3D printing are all different kinds of plastic. Or are they?

Well, they are and they aren’t. Currently, filament type consumer 3D printers can’t handle the temperatures required to melt metals, so we are stuck with different kinds of plastics, but there have been recent developments with different kinds of plastic filaments infused with other materials such as metal or even wood.

Since we are going for a very “wood” aesthetic in the houses we are building, the idea of printing useful 3D parts out of a kind of wood-like material was quite appealing to me. Here is a picture of the first part:

This is a 3D printed “wooden” hook mounted under an actual wooden box. It was sanded and finished just like normal wood. We even applied a polyurethane lacquer.

We purchased the filament from Print3Dd here in Thailand a few months back, but I never found a good part that was worth using it for until now. The material is 60% plastic and 40% wood fiber. The tiny wood fibers are somehow infused into the plastic, which is kinda cool, but also causes jams in the print nozzle more often than I’d like. (My print nozzle is only 0.4mm wide, so I may experiment with a slightly larger one if I want to print more of this stuff.) It actually jammed the nozzle 3 or 4 times until I found a speed and temperature that works more reliably.

The material really doesn’t feel like either plastic or wood. I guess it feels like what it is, a mix of the two. But wood and plastic are such different materials, I never imagined what a wood/plastic hybrid would feel like. Now I know. 😉

Mostly for my own record, here are the print settings I used:

- 50mm/sec print speed

- 0.27mm layer height (much thicker than the 0.1mm I normally print PLA)

- 205C nozzle temperature

- 60C heated glass bed with a coat of PVA glue stick to help the print stick

Interestingly, when I tried setting the temperature up to about 230C, it has that “slightly toasting wood smell” you get when you use a belt grinder on a piece of hardwood.

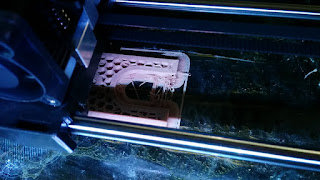

Here is a picture of it printing:

The print jammed just about 2mm from the top, which was frustrating, but this is a pretty simple piece, and so I decided to print the remaining top part separately and try using a wood glue to glue the pieces together. Here is a picture of the failed part on the bed with the finish-up print:

A bit of sanding to clean the connection and some carpenter’s glue, and the piece was basically complete:

This material is definitely a lighter color than most of the wood in our house, so I am curious if a wood stain will work on it. But first, I want to test its strength and durability in a real world scenario (i.e. as a hook being used daily). If that works out, we can explore how to make it look nicer later.

There is actually a fancier material out there called “Laywoo-d3” that changes to a darker color at higher nozzle temperatures. This can be used to fake a grain appearance by varying the color on different layers. It looks a bit cooler, but not as cool as you might imagine since you can only vary the color layer by layer meaning the “grain” is always horizontal. Some of the better examples I’ve seen can be found here. Maybe if I can source some of this stuff in Thailand, I might give it a whirl.